Decoration

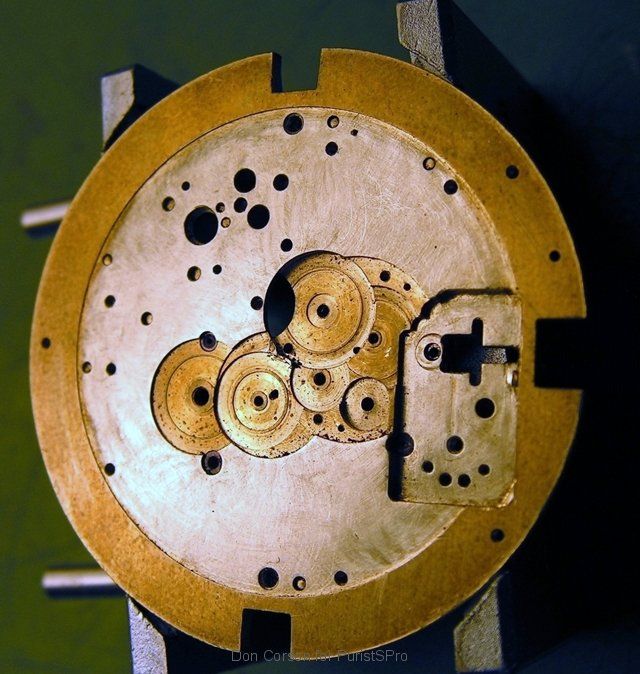

Now that the parts for the Dresdener Regulator are made the decoration of the plate and bridges will be performed.

Start by forming the final shape of the bridges.

The perlage is done at overlapping positions with a rotating tool. However, the surface needs

to be prepared so no blemishes will be seen amongst the “pearls”.

The first row of “pearls” is placed overlapping slightly less than half of their diameter.

The second row is finished and the third just begin.

The dial side perlage is finished.

Now it is time to finish the bridges.

Firstly, cleaning up the edges. The picture below showed the filing patterns left behind by a

coarser file.

Here after the second-cut filing and brushing.

For the bridge beveling, here are the tools used. Starting from the right are the very fine flat and rounded files,

followed by the super fine flat and rounded files, Degusit files (synthetic ruby) and lapping films (in various grades) to achive mirror polish.

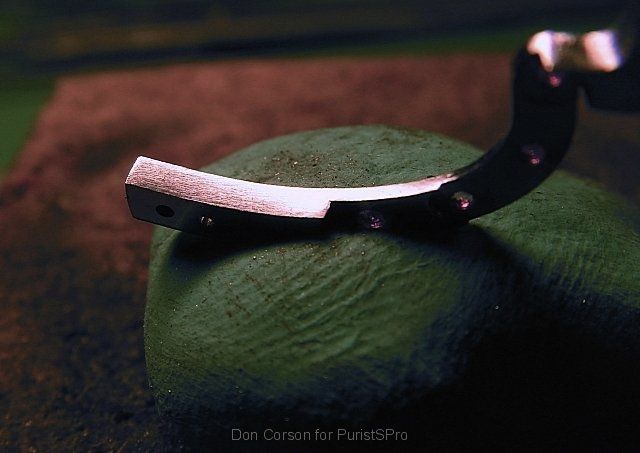

The bridge beveling starts by forming the bevel with a very fine file and cleaning that up with a super fine file.

Then the Degussit files and lapping till mirror finish with 3 different grades of lapping film. The picture shown is after the 9 micron lapping film.

Continue till the bevel is perfectly polished. This is just missing the final high luster polish with diamantine.

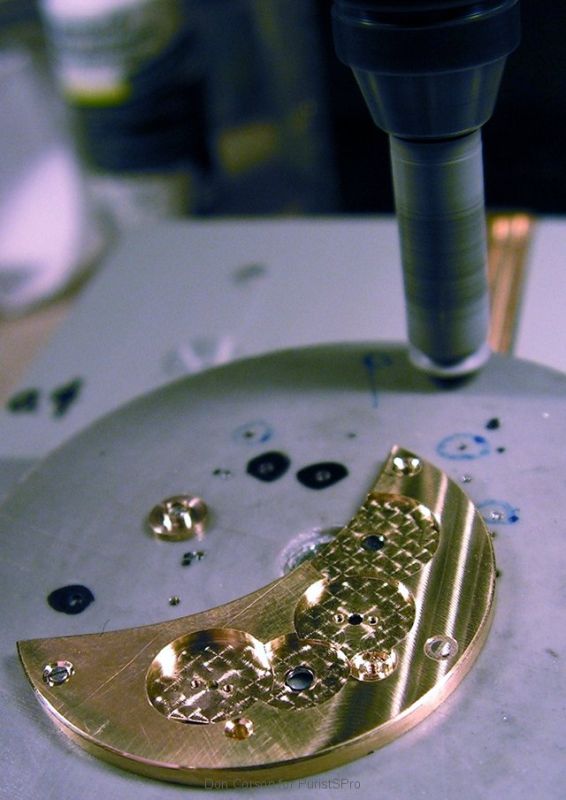

Next is to cut the jewel countersinks…

followed by polishing with diamantine on a wood polishing tool.

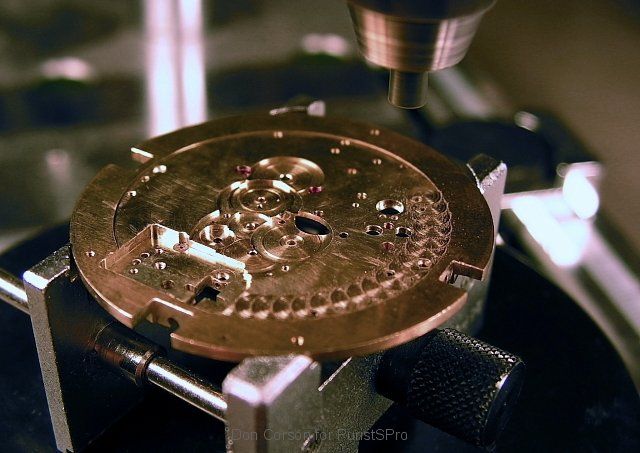

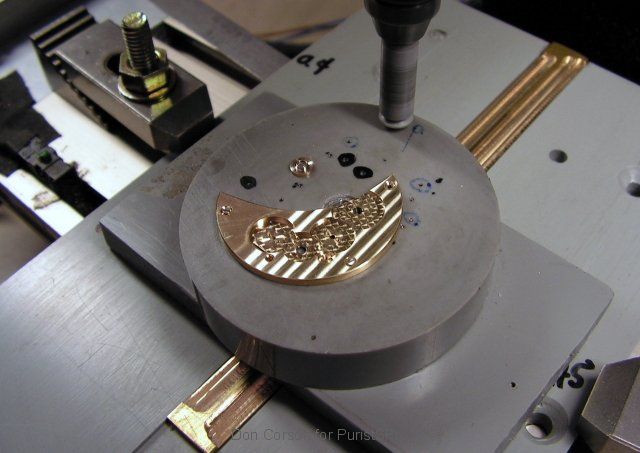

The bridges are screwed to a fixture for the côtes de Genève process.

Note that the surfaces are almost polished so that no blemishes will be seen through the côtes.

Côtes de Genève are made using a slightly inclined tool that ensures a distinct line at one side

and then moving the workpiece in a linear pattern under the tool.

Here 3 stripes are done. You can see the distinct line at the right and the curves running out to

the left. The next stripe will cover that ragged edge to the left.

7 côtes were done ...

The finished barrel bridge.

The dial frame is treated in the same way as the bridges; polished bevels and then côtes de Genève.

The same plating will also be given to the watch, dial side and movement side to give a uniform decoration.

Here initial filing of the bevel…

followed by the same 5 intermediate steps as with the bridge beveling.

The final polishing with diamantine…

followed by the côtes de Genève.

Here are all the pieces to be plated in ruthenium-anthrazit.

Ready to ship off to the plater...

After a couple of days, the parts are back in a nice warm charcoal color.

The re-assembly will start after some more parts, like the wheels, are finished in the next installment.

Источник:

http://home.watchprosite.com/show-fo...ti-501361/s-0/